The ECCO GROUP has developed products and technologies across a broad variety of industrial applications since 1969. We are providing almost all industries with products in the areas of friction management and natural fibres. As a holding company we offer natural fibres under the brand Setralit®, under the brand MiPo® we offer solid lubricants and under the brands setral®, TECCEM® and Fluoronox® we offer one of the most comprehensive portfolios of specialized lubrication solutions in the market.

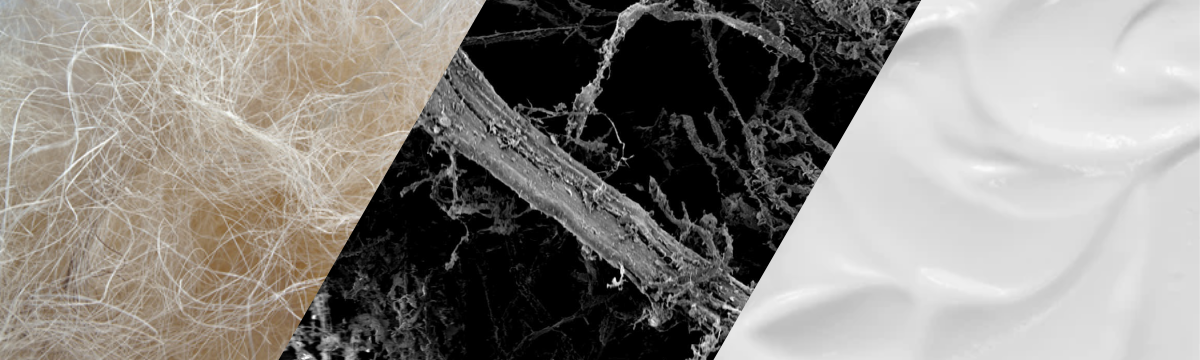

natural fibres for industrial applications

natural fibres for industrial applications

groundbreaking technologies in fibre and solids treatment

groundbreaking technologies in fibre and solids treatment

specialized industrial lubricants

specialized industrial lubricants

PFPE-lubricants & forming greases

PFPE-lubricants & forming greases

lubricants under your own brand

lubricants under your own brand